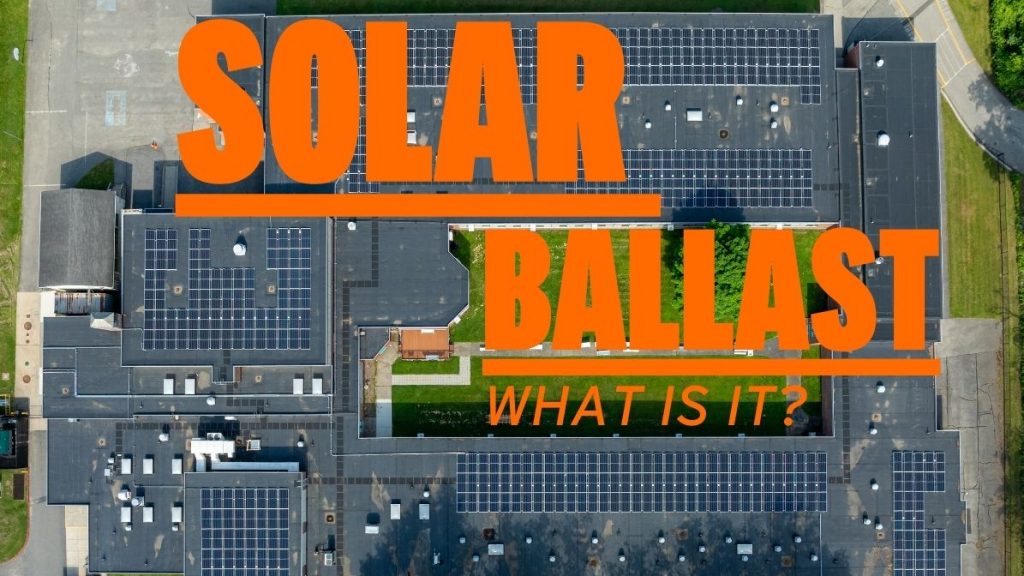

Want to avoid holes in your roof? Ballasted solar installations provide an alternative to traditional attached racking systems, but they may not be for everyone. Here’s why.

In the solar community, ballasts are a common alternative used on solar installations that are unable to penetrate neither the roof nor the ground. Building owners often do not want to make holes on low-sloped, flatter rooftops. Similarly, temperamental ground-mounts have the same concerns. Solar arrays installed on top of a landfill are unable to pierce the liner.

Based on the situation and the owner’s unwillingness to make holes on their property, solar ballasts are often introduced as the alternative solution. Installing the ballasts involves placing concrete blocks throughout a project in order to secure an array to the ground or the roof. This prevents the wind from lifting and moving the installations.

Leading solar design engineer at Orion Solar Racking Cael Schwartzman revealed that there are many factors that go into determining how much ballast a solar array needs. Some of the most common factors are: size and orientation of array; physical project location (wind, seismic factors); roof shape, height and strength; and type of racking used.

“A licensed structural engineering professional engineer (P.E.) should determine the size/amount of ballast needed,” Schwartzman said. “If a racking company has a P.E. on staff, then they can offer this service. If not, the customer or racking company can source a consultant P.E. to perform the calculation.”

“The racking design will dictate the maximum size of ballast blocks that can be used,” Schwartzman said. “A system should be able to hold multiple blocks in each ballast pan such that weight can be added to or subtracted from a specific spot on the array. This is necessary because ballast weight isn’t always uniform throughout an array. More weight may be required at corners or specific areas compared with other areas.”

The core component of ballasts — concrete blocks — has remained unchanged since they were first introduced. However, project and racking design has seen a significant shift, with a “less in more” approach gaining traction.

Solar Ballast

On the other hand, a growing concern with solar ballast is the degradation of concrete over time. According to Sam Veague, vice president of commercial sales at Ecolibrium Solar, concrete normally tends to break down when exposed to moisture, cycles of freezing/thawing, and UV light.

“Depending on the design of the racking system, cracked or broken ballast blocks may fall out of the racking and end up with some or all of the ballast laying on the roof,” Veague said. “Thus [the ballast] is no longer doing its job of adding weight to the system to hold it in place. Broken chunks of concrete on the roof can damage the roof membrane—maintenance personnel step on the pieces, grinding or tearing the roof membrane.”

Every roof and solar energy system comes with its own unique considerations. According to home designing specialists, it is crucial to have a professional engineer in the solar installer team you hire for your project. They can evaluate the size of your system, the strength of your racking equipment, climate and roof load. At the very least, it is important to consult with a professional engineer to see what design fits your building the best before signing the contract.